LED Light String Types - Part 2

- Chris Cummings

- Oct 23, 2022

- 2 min read

Updated: Oct 23, 2022

Well, if you have read Part 1 of this series, we now have some idea of what it takes to get individual control of color in a string of LEDs. Using Smart LEDs that have integrated Controller ICs makes it work.

This is where acronyms have taken two meaning. RGBIC usually means "Red, Green and Blue Individual Control" but has been interpreted as "Red, Green and Blue Integrated Circuit" due to the IC Controller in the LED. In general, we'll keep with the original meaning of Individual Control.

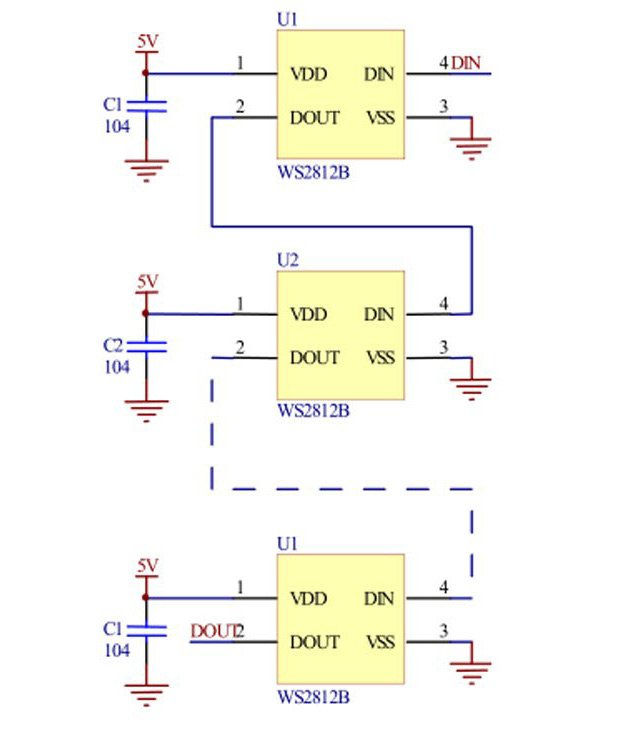

The next big differentiator is in the number of signals to use. The most popular strings use only a single Data Line to transfer data. As mentioned elsewhere in this blog, there are some drawbacks to this scheme, but for most systems it will not be a problem.

In more strenuous environments, like when there is a lot of electrical noise or long string lengths, it can help to have both a Clock Line and a Data Line. The protocol is different for this type of network, and it allows much more flexibility it terms of frame update data rates. Where Date Line-Only systems are generally fixed at 800KHz, we have run Clock + Data systems as high as 16MHz, but usually hover around 1MHz for EMI/RFI interference reasons.

This is the venerable APA102C LED (Datasheet courtesy Adafruit and my friends at Shiji Lighting). It has Both Clock and Data lines and runs off of 5VDC. Please visit Sparkfun for more info, by clicking on the pic.

There are newer versions of this LED that add Gamma-Corrected brightness and there are versions of external ICs that do the data interface and have the ability to drive transistors that can then drive clusters of LEDs, for larger or brighter bulbs. Look for the UCS2903 in coming products from Dyzine Tek!

One thing that both of these networking types share in common is the cascading nature of the daisy-chaining. The data gets reprocessed at every LED along the string and there is no way for the channel controller to talk directly to any LED other than the very first one.

Hence the improvement that a Multi-Drop network can bring. This is the scheme Hysiri chose to implement. Likely as part of the product portfolio they had wanted to make, like Christmas Tree lighting where there is a distribution ring at the very top of the tree and then like 20 individual drops that dead-end at the bottom:

The ring at the top is a clean little PCB with thick traces to carry enough current for 400 LEDs that are embedded in the "beads". The beads themselves are really quite impressive, as it would seem the LEDs are mounted to a transparent substrate, the way the light is well distributed around the entire circumference of the bead. The wires themselves twist and bend and it does not inhibit the display of color from the beads, as shown below:

This same architecture is used on our newest incoming product, the 400 LED Vertical Curtain Matrix due in early November, 2022. Also in our Icicle Lights due at the same time. Check back with us often as we continue to expand upon the technical details of Hysiry's Lighting Systems.

Comments